4

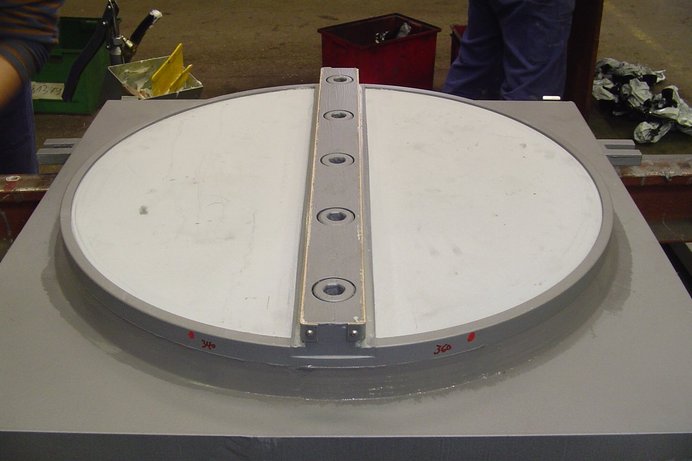

The structural rotations are adjusted thanks to an elastomeric pad, which responds with high vertical stiffness and low rotation resistance, confined into a steel pot.

Displacements are adjusted by a PTFE layer sliding on a stainless steel sheet. For guided or fixed bearings, external lateral forces are transmitted by suitable restraints or guides. The durability of the internal seal is a crucial point. Our patented PTFE/carbon internal seal has been tested for 2 km accumulated rotations without wear.

Key characteristics of MAURER Pot Bearings

- Cost-effective solution for moderate and small horizontal loads

- Use of highest quality seals according to EN1337-5

- Service life of 10-25 years

- Allowable temperatures from -40°C to +50°C

- Available in accordance with EN 1337-5 and AASHTO

Components

TF

- A steel pot with suitable connections to the structure

- An elastomeric pad, which is confined in the steel pot

- A patented Carbon/PTFE or MSM® seal ensures that the elastomeric pad cannot flow out of its seat

- An upper steel piston with suitable connections to the structure

TGA - TGE - TGEQ

- Steel pot with connections to the structure

- Elastomeric pad confined in the steel pot

- Patented carbon/PTFE or MSM® seal for sealing the steel pot to prevent possible escape of the elastomer under pressure

- Steel plate placed onto the elastomeric pad and confined in the steel pot (lid) with guiding unit for transmitting horizontal forces and PTFE sliding plate

- Stainless steel sliding plate (sliding partner) with a steel plate (support plate) and connection to the structure

4

Contact Head Office

MAURER SE

Frankfurter Ring 193

80807 Munich

Germany

Phone +49. 89. 32394-0

Mail