MAURER marks anniversary with testing press for seismic protection components

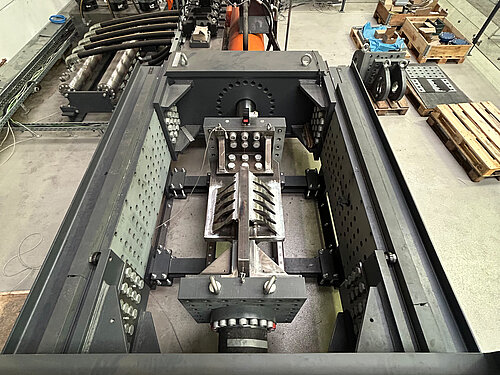

The new system is a tensile and pressure testing machine that can perform static and dynamic tests on construction elements in a steel frame. It is among the most powerful systems of its kind in Europe, capable of generating forces of ±3,200 kN, moving amplitudes of ±765 mm and achieving speeds of up to 3,000 mm/s.

Power meets precision

With its high hydraulic output and precise pressure control, the system enables exact measurements for demanding test procedures. Its heavy steel frame can absorb large movements and enormous forces of up to 600 tonnes during component testing. The frame forms a stable counterforce to the actuator, which performs precise load scenarios under realistic conditions such as earthquakes and wind.

MAURER can therefore test many of its products in house, particularly dampers, shock transmitters and path-dependent connection elements, alongside typical components and materials. The system can test specimens measuring up to 10 m in length, 1,200 mm in width and 1,000 mm in height. The system measures 30 x 10 m in total, including the protective fence, compressed air bottles, control station and screen. But that is not all. Its modular design enables future expansions for testing forces of up to 6,000 kN, whilst also enabling testing of bearings and isolators.

Three weeks faster

Being able to perform complex tests for orders in house instead of having to outsource them to external providers shortens MAURER’s production times by up to three weeks. There are also fewer interactions with external testing labs, which therefore reduces travel time and costs, as well as packaging material and transport, resulting in a real competitive advantage.

Driving development

The system also allows MAURER to test new components or functions of existing components better and at short notice: “The testing process allows us to feed real acceleration data from earthquakes or wind loads, known as accelerograms, into the machine control for the first time”, explains Redecker. “This is a huge step forward for our development and testing processes, making them more realistic and allowing us to know precisely how our components react under real scenarios”.

Testing system as a motor for innovation

As the company celebrates its 150th anniversary, the new test system promises a fresh push of innovation, particularly when it comes to better, more precise and new functions for many of its existing products. Many MAURER products are used in highly specific niche applications and at the limits of what is technically possible. Data for extreme earthquake loads, for example, cannot simply be taken from other sectors. The new testing press allows MAURER’s developers to validate theories, and better understand what products need to be capable of and where the limits of their performance and safety lie. Specific force-path or force-speed diagrams can be created, for example, which can then be compared with the project requirements and relevant standards. This can deliver new insights for modifications to components like dampers, bearings and expansion joints. MAURER’s development division uses this information for changes that affect the material, tolerances and geometry.

One of the best examples of this are the first successful tests with hysteresis dampers for the Natalia Sats Theatre in Almaty, Kazakhstan. New and more stringent seismic protection rules in the country meant that the theatre had to be fitted with 40 additional seismic dampers for a total response force of up to 2,400 kN.

These dampers were subjected to dynamic tensile and pressure testing with an amplitude of ±100 mm, in which they had to meet a precise pre-specified force-path curve. They were connected to one end of the test frame and the hydraulic actuator at the other end with steel brackets and bolts. After the test results showed a deviation of less than ±3% from the optimum curve (the standard allowed for a tolerance of ±15%), the Kazakh authorities immediately approved production of the dampers. The new test system meant that the first eight custom-made hysteresis dampers could be delivered to Almaty just eleven weeks after ordering.

In-house expertise

Design work on the new press began in 2023. The entire process was managed by a team of four experts from MAURER Engineering and Florian Obholzer Engineering. The components were ordered in 2024 before being commissioned in June 2025. Now, in the company’s anniversary year, the new system is a symbol for 150 years of successful internal teamwork, resulting from technological prowess, independence and trust in its own capabilities.